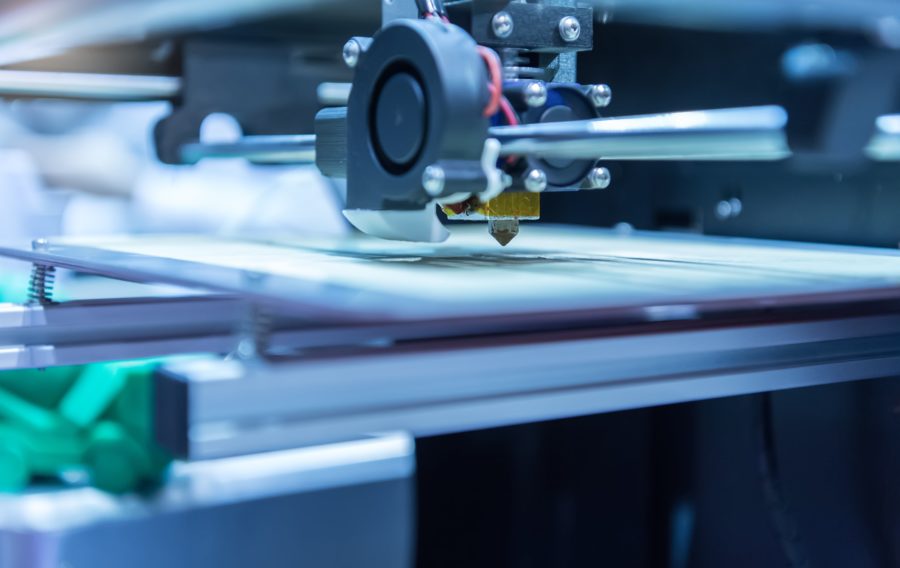

Across many sectors, 3D printing is becoming a more integral way of manufacturing, and its influence is growing in the defence industry.

Additive Manufacturing, or 3D printing, allows parts to be created quickly and cheaply for repairs, prototypes, and replacement components. Parts can be created which conform to specific standards and are identical. In defence, 3D printing can be especially useful on long deployments and on vehicles such as ships and submarines. A part can be requested and created within 24 hours rather than having to be delivered, which can take much longer. A central online base for designs can be accessed by personnel to request plans for parts when they are needed. The method also reduces the cost of manufacturing these parts and removes to need for delivery costs as they can be made on site. This can be especially useful during long deployments to conduct repairs. Additive manufacturing is becoming a larger part of the construction of vehicles and equipment as well as on building projects.

The UK Ministry of Defence has been increasingly using additive manufacturing techniques. Roke Manor Research Limited won a contract five years ago to identify and develop the UK’s military tech by 2030. DSTL launched the Land Environment Science and Technology Watch programme (S&T Watch) to provide an easier route for the industry to present ideas to the British army. This includes 3D printing as well as robotics, communications, augmented human performance, and quantum technologies. The MOD is looking for applications that support military engineering, close combat, aircraft, and artillery support. The technology was used for the first time by the British Army in South Sudan at the end of last year. While building a hospital for the UN British forces were able to forgo lengthy delivery times with a Lulzbot TAZ 6 printer that allows them to produce industrial-strength plastic items up to the size of a football. The printer can produce parts in 12 hours that can otherwise take weeks to be delivered to the remote African site. The printer has been used mostly for small parts such as plumbing components which allows building work to continue without delays.

The European Defence Agency (EDA) has also committed to increased use of additive manufacturing. The EDA held an event in 2017 to explore the potential for the technology to become a larger part of the defence industry. Earlier this year, the EDA launched Additive Manufacturing Techniques for Energetic Materials (ANTEM), a project exploring how the technology can be used for warheads and propellants. The project was signed by ISL, Ariane Group, EURENCO, NEXTER Group, Fraunhofer Institute for Chemical Technology (ICT), The Netherlands Organisation for Applied Scientific Research (TNO), Norwegian Defence Research Establishment (FFI), NAMMO, Chemring Nobel, Polish Military Institute of Armament Technology (MIAT), Swedish Defence Research Agency (FOI), Finish Defence Research Agency (FDRA), Oy Forcit AB, Raikka OY and Aalto University from Finland, France, Sweden, Poland, Netherlands, and Germany. The team will assess techniques and materials, with an aim towards faster and more cost-effective prototyping and rapid production.

The US Department of Defence’s Army Research Laboratory (ARL) signed a contract with 3D Systems to produce a large printer capable of producing large parts. The Navy, Air Force, and Marines already make use of additive manufacturing for repairs, logistics, and sustainment. The DOD is aiming to create mobile units for deployment which are capable of running 3D printing and carrying all the equipment and materials needed. The Army’s Tank Automotive Research, Development, and Engineering Centre (TARDEC) along with the Research, Development and Engineering Command (RDECOM) and the Aviation and Missile Research, Development and Engineering Center (AMRDEC) are experimenting with metal and plastic parts in 3D printing. The 3D Systems contract, worth $15million, will focus on manufacturing for combat vehicles, helicopters, long-range munitions and air and missile capabilities. The DOD aims to install metal 3D printing platforms in all depots and labs in the future to advance additive manufacturing in all its operations. 3D Systems has also worked with NASA, providing metal parts for the Mars Exploration Rover and telecommunications satellites.

Mordor Intelligence has released a market report which examines the growth potential of 3D printing in aerospace and defence between 2019 and 2024. The report notes that the driving market behind 3D printing is aerospace and defence. Airlines use additive manufacturing to bypass supply constraints, free up space in warehouses, cut costs, and limit waste material. Thermoplastics and lightweight, cost-effective synthesised material such as polyetherimide plastic, or Ultem, is increasingly used in the aerospace sector due to its ability to withstand extremely high and low temperatures and its higher strength compared to its weight. The need for lightweight manufacturing parts in aerospace industries is important to the additive manufacturing market. The ability to create components from lightweight but durable materials means that modern aircraft are more fuel efficient and therefore less expensive to run. Lockheed Martin and Arconic announced a Joint Development Agreement (JDA) to improve manufacturing processes and lightweight materials, including metals. The report details how the aircraft industry holds the largest part of the market in 3D printing for defence and aerospace. Currently, over a third of the market is held by aircraft manufacturing. The modern market is relatively fragmented, but the major players include 3D Systems and Stratasys Ltd., along with several other businesses.

Mordor Intelligence predicts a strong future for additive manufacturing in aerospace and defence, with a 20% growth expected over the next five years. Advancing technology in materials and 3D printers will strengthen the market and push the market for aircraft and Unmanned Aerial Vehicles (UAVs) in particular due to the advancement of lightweight materials like Ultem. Spacecraft manufacturing will also continue to form a large part of the market, thanks to advancing metal materials. The report suggests North America will experience the highest level of growth in the market. This is thanks in part to the Federal Aviation Administration’s (FAA) approval of increased use of printed parts in commercial jet engines. The European Aviation Safety Agency has also approved more 3D printing in aircraft. Innovations like Power Door Opening System (PDOS) brackets by GE entering into mass production will also strengthen the North American industry.

If you would like to join our community and read more articles like this then please click here.